- Products

- Laser Welding Machine

- Handheld Laser Welding Machine

- 200W Fiber Laser Welding Machine

- 400W Optical Fiber Transmission Welding Machine

- 600W Fiber Transmission Laser Welding Machine

- High Power Rotary Laser Welding Machine

- Laser Spot Welding Machine

- Mold Laser Welding Machine

- Automatic Wire Laser Welding Machine

- Advertising Words Laser Welding Machine

- Boom Laser Welding Machine

- High Power Straight Out Fiber Laser Welding Machine

- Laser Cutting Machine

- Laser Cleaning Machine

- Laser Marking Machine

- Laser Welding Machine

- Applications

- Accessory

- Blog

- About Us

- Recruit Distributors

- Contact Us

- Products

- Laser Welding Machine

- Handheld Laser Welding Machine

- 200W Fiber Laser Welding Machine

- 400W Optical Fiber Transmission Welding Machine

- 600W Fiber Transmission Laser Welding Machine

- High Power Rotary Laser Welding Machine

- Laser Spot Welding Machine

- Mold Laser Welding Machine

- Automatic Wire Laser Welding Machine

- Advertising Words Laser Welding Machine

- Boom Laser Welding Machine

- High Power Straight Out Fiber Laser Welding Machine

- Laser Cutting Machine

- Laser Cleaning Machine

- Laser Marking Machine

- Laser Welding Machine

- Applications

- Accessory

- Blog

- About Us

- Recruit Distributors

- Contact Us

- Products

- Laser Welding Machine

- Handheld Laser Welding Machine

- 200W Fiber Laser Welding Machine

- 400W Optical Fiber Transmission Welding Machine

- 600W Fiber Transmission Laser Welding Machine

- High Power Rotary Laser Welding Machine

- Laser Spot Welding Machine

- Mold Laser Welding Machine

- Automatic Wire Laser Welding Machine

- Advertising Words Laser Welding Machine

- Boom Laser Welding Machine

- High Power Straight Out Fiber Laser Welding Machine

- Laser Cutting Machine

- Laser Cleaning Machine

- Laser Marking Machine

- Laser Welding Machine

- Applications

- Accessory

- Blog

- About Us

- Recruit Distributors

- Contact Us

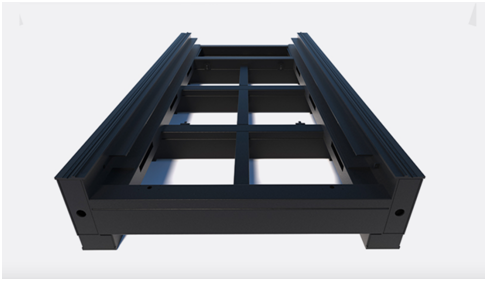

Exchange Platform Fiber Laser Cutter

Revolutionizing the Welding Industry

Overview

The exchange platform laser cutting machine has two work surfaces, which are exchanged for processing during work. When one work table is cutting, the other work table can simultaneously perform unloading and feeding work. After the work surface to be cut is processed, another work table The laser cutting machine can continue processing without waiting for unloading and loading, saving standby time and improving work efficiency. Another way of saying this equipment is an interactive laser cutting machine.

Advantages of the exchange platform laser cutting machine:

- It is convenient to load and unload the material, and the material is loaded and unloaded at the same time, and the production and processing of the product can be completed by 2-3 people with CNC operators;

- There are many kinds of processing materials, which can be used to process a series of plates such as various metals, carbon steel, stainless steel, etc.;

- There is no & tool & wear during processing;

- Non-contact processing, laser beam energy and moving speed can be adjusted, so various processing can be completed, suitable for processing;

- Easy to guide, cooperate with CNC system, easy to operate;

- It can be upgraded on the basis of the original cutting platform, and a fully enclosed protective cover can be installed, which can be fully enclosed for processing and has low noise;

- The system itself is a computer system, which can be conveniently arranged and suitable for specialized processing, especially for some sheet metal parts with complex contours, the product life cycle is short, from the perspective of skills, economic cost and time, the production of molds Not cost-effective, and laser cutting is especially advantageous.

Features

The exchange platform laser cutting machine equipment has the advantages of wide application range, flexible process, good processing quality, clean production process, and easy to realize automation, flexibility, intelligence and improve product quality and labor productivity.

Unique double-row flue of the plate welding bed

cast aluminum beam, withhigher speed, higher precision and higher efficiency

Low energy consumption, easy to operate, low maintenance cost

Cutting Samples

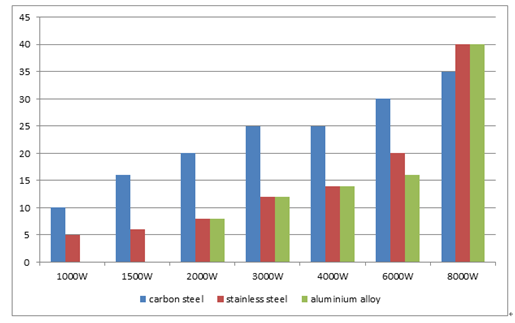

It can be specially used for 0.5-25mm carbon steel plate, 0.5-16mm stainless steel plate, galvanized plate, cold-rolled plate and electrolytic plate.

0.5-16mm aluminum alloy plate, 0.5-10mm brass and copper and other metal materials.

| Model | FSG3015-A/B/C |

| Power | 500W/1000W/2000W |

| Laser source brand | RAYCUS |

| Laser head brand | WSX |

| Control system | Cypcut |

| Cutting working area | 3000*1500/4000*2000/6000*2000 |

| Cooling mode | Water cooling |

| Max linkage speed | 70m/min |

| X.Y axis positional accuracy | ±0.03mm/m |

| X.Y axis repeated location accuracy | ±0.02mm/m |

| Z axis stroke | 240mm |

| Machine color | Support custom made |

| Guide rail Brand | HIWIN |

| Cutting Speed | 0-70000mm/s |

| Cutting Thickness | 4mm-20mm, Depends on material |

| Reducer brand | Japan Shimpo |

| Servo Motor Brand | Yaskawa |